High-Performance Concrete (HPC)

➤ The Performance Requirements of Hardened concrete or high-performance concrete are more or less well defined With respect to Shape, finish, strength, durability, shrinkage, and creep,

➤To achieve these objectives economically, the fresh concrete in addition to having a suitable composition in terms of quality and quantity of the materials should satisfy a number of requirements from the mixing stage till it is transported, placed in a framework and compacted,

Definition of high performance concrete➤

➤ High-performance concrete (HPC) can be defined as concrete that possesses high strength, work-ability, density, low permeability and resistance to chemical attack,

➤HPC is concrete that has been designed to be more durable and if necessary stronger than conventional concrete,

Introduction of high performance concrete➤

➤Deterioration, long term poor performance, and inadequate resistance to hostile environment led to the accelerated research into microstructure of concrete and hence the evaluation of high-performance concrete,

➤ Long-term performance of structures has become vital to the economics of a nation,

➤As a result, new materials and composites have been developed,

➤Today concrete structures with high compressive strength of 140 MPa are being built in United States and Europe,

Benefits for the designer➤

➤ The benefits of high-performance concrete to the designers are much more than those of high-strength concrete,

➤Designers can design smaller cross-sections,

➤Slender members,

➤High Elastic modulus,

➤Initial high early strength,

➤Rapid attainment of final creep level,

Benefits for the producer of high-performance concrete➤

➤In the Production of high-performance concrete Quality control in terms of raw materials and finished products is imperative,

➤Increased quality control leads to increased profitability and productivity of usual concrete,

How is high-performance concrete made?

Mechanism of high performance concrete➤

Under compressive loads, failure in normal concrete occurs either➯

➱Within the hydrated cement paste,

➱Along the interface between the cement paste and aggregate particle,

➱Aggregate,

To improve the strength and other properties it is necessary to strengthen these weak areas,

Improving the strength of hydrated cement paste can be done by➮

➤Reducing the water binder ratio and hence the usage of super plasticizing admixtures having high range water reduction capacity,

➤Using supplementary Cementitious materials,

Increasing the strength of the transition zone➮

➤Reducing water and cement ratio.

➤Using supplementary cementitious materials.

➤Ensuring proper coating of aggregates with cement paste.

➤Use of smaller-sized aggregates leads to homogeneous distribution of water.

Aggregate Failure➱

➤Due to Aggregates failure Cement paste material remains intact.

➤Failure plane propagates through the Coarse aggregate particles.

What are the two typical ingredients used in high performance concrete?

Ingredients of High performance concrete➤

➤Cement (O.P.C, blended Cements etc.)

➤Water,

➤Aggregates

➮Fine Aggregates

➮Coarse Aggregates

➤Admixtures

➤Supplementary Cementitious materials(Fly Ash, Silica fume, GGBS, etc.)

Cement➱

Cement Selection is critical to rheology and compressive strength.

➤Fineness of Cement

➮ From the Strength point of view, the finer the cement the better the concrete,

➮ From the Rheological point of view, The finer the cement the more reactive concrete,

Water➱

➱Chilled water is added to reduce the concrete temperature,

➱ice flakes are added as a part of mixing water,

Aggregate➱

Strength of aggregate depends on the nature of the parent rock Prepared from.

➱Avoid rocks with weak cleavage planes of severely weathered.

➱Fine aggregates should be rounded and uniformly graded.

Admixtures➱

Super plasticiser➮

➱Disperses Cement Particles within the mix.

➱Reduces the Amount of mixed water.

➱Controls the rheology of very low water/binder ratio mixtures.

➱solve slump loss problems.

Supplementary Cementitious materials➱

➱Ground Granulated blast-furnace slag.

➱Fly ash (low Calcium, high calcium).

➱Silica flume or micro silica.

➱ Natural pozzolana (meta kaolin, rice husk ash).

Aspects of High-performance concrete in fresh state➱

➱Batching and mixing.

➱Tests in fresh HPC concrete.

➱Placement and Compaction.

Batching and Mixing➱

➱Batching of individual materials must be accurate.

➱Longer mixing time is required to ensure homogeneity as the mix is usually sticky.

➱Mixing time of 90 seconds is recommended.

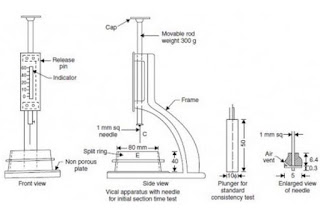

Tests on Fresh HPC Concrete➱

Following tests on fresh high-performance concrete is carried out.

➱Slump / Flow table

➱Air content

➱Temperature

➱Unit weight

➱Setting time of mix

➱Bleeding

➱Slump retention and Pump-ability

Placement and compaction of High performance concrete➱

➱Concrete mix is carried from the batching plant with the help of transit mixtures.

➱Method of placing is mostly by pumping.

➱Compaction is by both External as well as internal means.

Test on Hardened high performance concrete➱

The following tests are carried out on hardened high-performance concrete.

➱Compressive strength (Cube and Cylinder)

➱Split Tensile strength.

➱Modulus of elasticity.

➱Water permeability.

➱Rapid Chloride penetration test(RCPT)

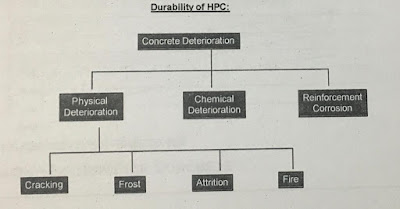

Durability of HPC➱

➱Durability of Concrete can be defined as the resistance of concrete to deteriorating influences which may be inside the concrete itself or which may be present in the environment to which it is exposed.

➱ The durability of Concrete Largely depends on the ease with which fluids, both liquids and gases, can enter into and move through the concrete. This property is known as the permeability of concrete.

The durability of HPC: Carbonation➱ ͏͏͏

➱ In Presence of Moisture CO2 Present in Air reacts with Ca(OH)2 to form CaCO3.

➱ Carbonation causes the reduction in pH of pore water from between 12.6 to 13.5 to about 9.

➱ Steel embedded in concrete forms a thin passivity layer of oxide which remains only with high pH.

➱ As The pH reduces the oxide layer is removed and the corrosion of steel starts, its volume increases and creates tensile stresses in concrete.

Durability of HPC: Chloride attack➱

➱ The primary action in chloride attack is the corrosion of steel and consequently damage to surrounding concrete.

➱ As long as the oxide film on steel is present, The steel remains intact.

➱ Chloride ions destroy the film and in the presence of water and oxygen corrosion occurs.

➱ Corrosion does not occur in dry or fully submerged concrete but occurs in alternate wetting and drying and relative humidity of 70-80 %.

➱ Chlorides can be present in concrete through the use of contaminated aggregates, seawater or chlorides in admixture.

➱ According to I.S. total chloride content in cement should not exceed 0.05% by mass of cement.

➱ I.S. 456-2000 states that total Chloride content in concrete should not exceed .4 and .6 kg/cum for pre-stressed and reinforced/plain concrete containing embedded metal respectively.

Durability of HPC: Sulphate attack➱

➱ Common sulphates present in soil and groundwater are sodium, potassium, magnesium, and calcium.

➱ Sulphates present in solution react with hydrated cement paste.

➱ Sodium sulphate attacks Ca(OH)2 and gypsum is deposited, Ca(OH)2 Can Also be completely leached out.

➱ Magnesium sulphate attacks calcium silicate, calcium aluminate hydrates and also Ca(OH)2.

➱ Calcium sulphate attacks calcium aluminate hydrate (C3A) forming ettringite.

➱ Ettringnite formed has a higher volume and causes expansion in concrete.

Durability of HPC: Alkali Aggregate Reactivity➱

➱ Reaction between active silica constituents of aggregates and alkali in cement forms alkali-silicate gels in planes of weakness or either in pores or surface of aggregates.

➱ The reaction starts with an attack on siliceous minerals in aggregates by alkaline hydroxide in pore water derived from the alkalies(Na

2O or K

2O) in cement.

➱This gel is of unlimited swelling type, absorbs water and causes an increase in volume.

Development Of HPC Mixes➱

➱ Computing the Target strength.

➱ Estimating mixing water content.

➱ Calculation of water to cementitious material ratio.

➱ Selection of percentage of SCM.

➱ Selection of fine to total aggregate ratio.

➱ Calculation of aggregate contents.

➱ Selection of Superplasticiser dosage.

➱ Trial mix and testing.

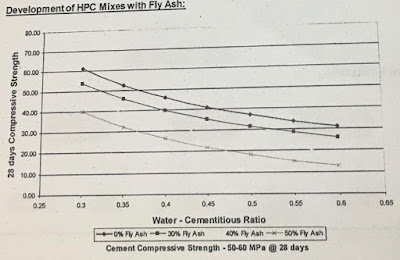

Development Of HPC Mixes with Fly Ash➱

Approx mixing water for 20 mm aggregate and 100 mm slump

| Fly Ash Content |

Water kg/Cum |

| 30 |

155+5 or 155-5 |

| 40 |

150+5 or 150-5 |

| 50 |

145+5 or 145-5 |

➱ Selection of fine to total aggregate – Normally 25-40 % is used depending upon the grade of concrete, nominal size of aggregate and workability required.

➱ Calculate aggregate content based on the absolute volume method.

Where is high performance concrete used?

What is high performance concrete used for?

All Necessary Factors➱

Specifications for Bandra – Warli Sea Link Project➱

➱ Selection of water/binder ratio sufficient enough to achieve the target strength with special consideration from a durability point of view.

➱ Use of Supplementary Cementitious material together with a low water to binder ratio to make concrete structure more dense with a minimum volume of capillary pores, hence making it more durable.

➱ Water content in the mix is required to be kept at the lowest practical so as to minimize drying Shrinkage.

➱ Limiting the heat generation (especially in mass concrete) by keeping the total OPC content in the mix to the minimum required.

➱ Use of high-range water reduction admixtures to achieve the required workability.

|

| Bandra-Warli Sea link under construction |

|

| bandra-Warli Sea link |

Project Specification➯

Grade of Concrete- M60

Target Strength – 74 MPa

Max.Water / Binder ratio – < .35

Permeability – Less than 25 mm as per DIN 1048

| Ingredients (Kg/cum) |

Earlier Mix |

Modified mix |

| Cement |

320 |

300 |

| Fly ash |

110 (25 %) |

196 (40 %) |

| Micro silica |

43 |

40 |

| Total cementitious material |

473 |

536 |

| total water |

127 |

136 |

| W/C ratio |

.27 |

.25 |

| Coarse aggregate |

947 |

1077 |

| fine aggregate |

947 |

750 |

| Admixture |

15.1 |

10.9 |

| Properties |

Earlier Mix |

Modified Mix |

% (Modified/Earlier) |

| Compressive Strength (MPa) |

| 3 days |

39.8 |

39.3 |

98.7 % |

| 7 days |

56.9 |

54.8 |

96.3 % |

| 28 days |

78.1 |

74.7 |

95.6 % |

| 56 days |

79.4 |

80.9 |

101.9 % |

| 91 days |

80.9 |

92.2 |

113.9 % |

| Durability properties |

Field results |

| Water Permeability @ 28 days |

NIL |

| RCPT @ 28 days |

657 Coulombs |

| RCPT @ 91 days |

432 Coulombs |